Introduction

Over the past 20 years, the natural biopolymer chitosan has found wide application in the food industry, including its unique properties, such as a builder, thickener, stabilizer, emulsifier [6, p.136]. The beneficial effect of chitosan on the human body when added to food is proved. The ability to bind and remove radionuclides, heavy metals and toxins from the body is another important quality of chitosan. In our country, there are certain forms of chitosan production - crustaceans, arthropods and fungi [3, p. 34].

The hypothesis of scientific research was: in the laboratory, you can get the substance chitosan, completely replacing synthetic polymers, which gave rise to a lot of problems associated with protecting human health and protecting the environment. The aim of the research: to determine the properties of food chitosan from autumn mushrooms (real) (Armillaria mellea), from the shell of narrow-toed crayfish (Astacus leptodactylus) and the Colorado potato beetle (Leptinotarsa decemlineata).

Based on the aim, the following research objectives were set: conduct an information search in the field of rational use of natural raw materials processing; obtaining chitin (demineralization, deproteinization) and chitosan (chitin deacetylation) from autumn mushrooms, carapace of crayfish and Colorado potato beetle; determination of the effectiveness of the use of food chitosan as a thickener, structure-forming agent, stabilizer, emulsifier; to evaluate the solubility of chitosan in organic acids and the effectiveness of its solutions in the preparation of film coatings, to increase the shelf life of products using the example of cherry tomato (Solanum lycopersicum); a comparative and qualitative analysis for two years (chitosan from the carapace of crayfish and the Colorado potato beetle in 2018, chitosan from autumn mushrooms in 2019).

The object of research was the natural materials of the shell of crayfish, Colorado potato beetle and autumn mushrooms. The subject of research is biopolymer chitosan.

Literature review.

Chitin, along with cellulose, is the second most common polysaccharide on the Earth. Chitin is a linear polysaccharide, however, unlike cellulose, the second carbon atom of the elementary unit has not a hydroxyl group, but an acetamide group as a substituent.

As a result of numerous studies, scientists have revealed that the structure of chitin is not final, since with further processing it turns into chitosan. Chitin deacetylation, that is, cleavage of the acetyl group from acetic acid residues, was the first modification to produce chitosan [1, p. 26]. Since chitin has a compact structure, it is insoluble in most solvents. Therefore, for ease of use, it is used in modified forms, in particular [6, p.136] in the form of chitosan. This structural modification of chitin is often obtained by alkaline hydrolysis by partial deacetylation of chitin [3, p. 35]. Chitosan, unlike chitin, has an additional reactive functional group (NH-2 amino group), therefore, in addition to simple and complex esters, various types of N-derivatives can be obtained from chitosan, which significantly expands the possibilities of its use. Chitosan is soluble in acetic or hydrochloric acids at pH below 5-6 (its own pH is from 5.5 to 6.5).

Research methods.

The work was performed in the laboratory of the MEBI Bashkir Gymnasium and in the biotechnology laboratory of the Beloretsk`s technopark, from 2018 to 2020. The work used experimental, chemical, biochemical, microbiological research methods.

The objects of research were: the walls of autumn mushrooms (real), the shell of narrow-toed crayfish and the Colorado potato beetle. Chitin obtained from them, chitosan for subsequent research on food products: in film coatings for cherry tomatoes and emulsifier in sunflower oil; “iodine-chitosan” complex and growth stimulator on cereal plants that contain chitosan from autumn mushrooms; as a milk thickener and for coagulation of whey proteins, chitin and chitosan isolated from carapace of crayfish, Colorado potato beetle. The study of the antimicrobial properties of chitosan from the wall of mushrooms of autumn mushrooms (real) on a sweet nutrient medium.

Upon receipt of chitosan, the methodology of Abdullin V.F. - he developed a technology for producing chitosan; crushing of carapace shells, demineralization, deprotonation, deacetylation [1, p. 25]. When grinding the shell, the optimal average particle size is 3-4 mm, which allows to increase the active surface of the material during chemical transformations. The demineralization step is carried out to remove minerals that block the access of reagents to chitin. The process is carried out by treating the crushed shell with a weak solution of hydrochloric acid, which dissolves mineral impurities - mainly calcium carbonate [1, p. 26]. The stage of deprotonation is carried out in order to remove proteins and lipids from the carapace. This is achieved by treating the crushed shell with a weak solution of sodium hydroxide. Chitin is released, which turns into chitosan by the deacylation reaction [1, p. 27].

Photo No. 1-3 The process of obtaining chitosan

The main part.

The formation of a chitosan film on the surface of tomato fruits was carried out in stages, their visual selection was carried out by size, colour, lack of spots, mechanical damage and fungal infections on the surface of vegetables. The fruits were immersed in a solution of 0.5%, 1%, 1.5% and 2% chitosan in a 0.5% solution of acetic acid. Solutions with different concentrations of chitosan containing calcium gluconate (CaGlu) were prepared by dissolving 0.5% calcium gluconate in water before mixing with acetic acid [8, p. 161]. Each procedure included the processing of five tomato samples from each group. Vegetables in the amount of 28 tomatoes were randomly distributed into 5 groups, of which four groups were considered experimental and processed chitosan solutions of different concentrations, while the first group included untreated control samples. Processing vegetables consisted in immersing the fruits for 1-2 minutes (2-3 times) in the resulting solution [7, p. 68].

Photo No. 4-6 The process of formation of a chitosan film on the surface of tomato fruits.

Tomato fruits were dried for 2 hours at an air temperature of 20 ° С. After drying at an air temperature of 15 ° С, the tomatoes were stored in plastic containers (5-6 tomatoes in 1 container) at a relative humidity of 60-70%. Samples were analysed at intervals of 2 days [8, p. 161]. Tomato fruits coated with a film and control samples retained their original quality indicators for 8 days of storage. After storage for 16 days, control samples lost their presentation, while the quality of the fruit coated with chitosan film was maintained at a sufficient level. Chitosan film from a 2% solution in the best way preserved the appearance of the fruit. Scientists have proven that chitosan films are able to enrich foods with antioxidant substances, antimicrobial compounds, as well as minerals and vitamins [2, p. 304]. Thus, it was experimentally proved that coating tomatoes with a 2.0% solution of chitosan was the most effective.

Photo No. 7 Change in the organoleptic evaluation of chitosan-coated tomatoes.

Results and discussion.

We studied the growth of microorganisms in a sweet nutrient medium containing chitosan from the walls of autumn mushrooms and control samples without chitosan. It was determined that the total number of microorganisms in the control sample without natural polymer is much higher. However, no pathogenic microflora was found in samples with chitosan in the first 10 days, which indicates the presence of preserving properties of chitosan, which proves the possibility of its use as a natural preservative.

Chitosan in the food industry is also used for coagulation of whey proteins in the dairy industry, for the production of iodized food products based on the creation of iodine-chitosan complexes, and for other purposes. To test these properties, we took clean washed polished rice, iodine, a glass, a capacity of 200 ml with water and chitosan. A few drops of iodine were added to a glass of water and rice. Instantly, water and rice became dark blue, which proves the starch content in the rice. Then we added 1 g of chitosan to the solution, and after thorough mixing, we noticed discolouration of the solution and bleaching of rice. Having a powerful positive charge, the chitosan molecule binds to negatively charged molecules of the iodine solution. This explains the ability of chitosan to remove and bind heavy metals [12]. Another experience showing chitosan as a gelling factor. To study these properties, prepared a glass with a capacity of 200 ml with water, sunflower oil, chitosan. 20 ml of sunflower oil was poured into a glass of water, adding 1 g of chitosan to the solution and mixing thoroughly, we got a gel-like mass. The results showed that chitosan “attracts” lipids, binds them, making them inaccessible for absorption, and removes from the body, thereby preventing the formation of fatty deposits. Scientists call chitosan “a magnet for fats”: one molecule of chitosan is able to bind fat molecules 10-12 times their weight [15].

Photo No. 8-11 Chitosan as a gelling factor. Formation of the iodine-chitosan complex

In the food industry, chitosan plays an important role as a thickener. In the dairy industry, chitosan is widely used for the production of dairy products: dairy products, sour cream, cottage cheese, certain types of cheese, drinks [13]. Natural substance that does not have a negative impact, prolongs shelf life and improves the quality of dairy products. With the addition of a food thickener, the viscosity of the solution increases, thereby accelerating the processes of fermented milk fermentation, the formation of curd mass. Stir the milk under investigation and carefully pour along the wall into four glass containers. We do not add anything to the first vessel, we leave it as a control sample. In the second container, to 50 ml of milk we add 1.8 g of chitosan of crayfish, in the third - to 25 ml of milk 0.9 g of chitosan of the Colorado potato beetle, in the fourth - to 50 ml of milk we add 1.8 g of chitosan from the walls of autumn mushrooms. The resulting solution was well stirred, left for 2 hours, and the density of solutions with a hydrometer was measured at room temperature [13].

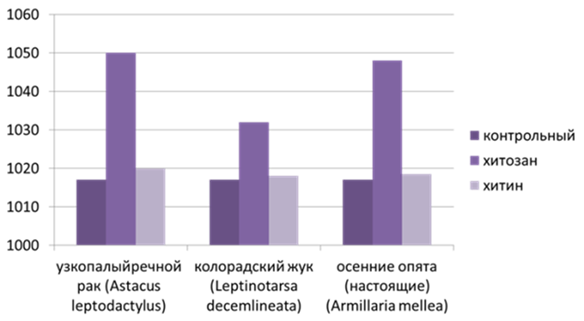

Dip the clean and dry device into milk, leave it alone for two minutes. We take the readings on the upper edge of the meniscus. According to the results of the study of chitosan, as a milk thickener, it was found that in the control sample the density is 1017 g / cm3, in the second container with chitosan of crayfish - 1050 g / cm3, in the third cylinder with chitosan of the Colorado potato beetle - 1032 g / cm3, in the sample with chitosan from the walls of autumn mushrooms-1048 g / cm3. Thus, it is clearly seen that chitosan of crayfish has excellent food thickener properties. Chitin is known to have the same properties as chitosan. To compare the properties of chitin and chitosan as thickeners, we decided to determine the effect of chitin on milk. Using the same methodology and the same algorithm of action (1.8 g of chitin of crayfish per 50 ml of milk, 0.9 g of chitin of the Colorado potato beetle, 1.8 chitin of autumn mushrooms), we studied the effects of chitin on the test milk. Thus, it is clearly seen that chitosan of crayfish has excellent food thickener properties. Chitin is known to have the same properties as chitosan. To compare the properties of chitin and chitosan as thickeners, we decided to determine the effect of chitin on milk. Using the same methodology and the same algorithm of action (1.8 g of chitin of crayfish per 50 ml of milk, 0.9 g of chitin of the Colorado potato beetle, 1.8 chitin of autumn mushrooms), we studied the effects of chitin on the test milk.

Our assumptions were confirmed, the viscosity of the solution changed: the density with chitin of crayfish was 1020 g / cm3, the density with chitin of the Colorado potato beetle was 1018 g / cm3, the density with chitin of autumn mushrooms was 1018.5 g / cm3. Thus, the effect of chitosan as a thickener is much higher than the effect of chitin.

Chart 1. Chitin and chitosan as food thickeners

From the above, the following conclusions can be drawn:

1. An information search showed the feasibility of using chitin and chitosan from autumn mushrooms (real) (Armillaria mellea), from the shell of narrow-toed crayfish (Astacus leptodactylus) and the Colorado potato beetle (Leptinotarsa decemlineata) as a source.

2. The processes of obtaining chitin — demineralization and deproteinization and chitosan — deacetylation of chitin were determined. Unlike practically insoluble chitin, chitosan, soluble even in solutions of organic acids, has wider possibilities for use in the food industry.

3. Obtained food film coatings based on a 2.0% solution of chitosan in 0.5% acetic acid, providing a decrease in the rate of oxidation of products and an increase in the shelf life of tomatoes up to 24 days.

4. The properties of chitosan as a food thickener are determined. Natural substance that does not have a negative impact, prolongs shelf life and improves the quality of dairy products. With the addition of a food thickener, the viscosity of the solution increases, thereby accelerating the processes of fermented milk fermentation, the formation of curd mass.

5. The results showed that chitosan “attracts” lipids, binds them, making them inaccessible for absorption, and removes from the body, thereby preventing the formation of fatty deposits, that is, food chitosan is an excellent emulsifier.

6. Having a powerful positive charge, the chitosan molecule comes into contact with negatively charged molecules of the iodine solution, creating the “iodine-chitosan” complex, it is advisable to use this property of chitosan in the production of iodized food.

7. Comparative characteristics of chitin and chitosan obtained from autumn mushrooms (real) (Armillaria mellea), from the shell of narrow-toed crayfish (Astacus leptodactylus) and the Colorado potato beetle (Leptinotarsa decemlineata), and their organoleptic properties are carried out.

Библиографическая ссылка

Измайлова Л.Т. THE STUDY OF PROPERTIES OF FOOD CHITOSAN IN SCHOOL CONDITIONS BELORETSK, REPUBLIC OF BASHKORTOSTAN // Международный школьный научный вестник. 2020. № 4. ;URL: https://school-herald.ru/ru/article/view?id=1360 (дата обращения: 16.02.2026).